Phone/WhatsApp 008618939512185

Phone/WhatsApp 008618939512185

Email: info@hcrefractory.com

Email: info@hcrefractory.com

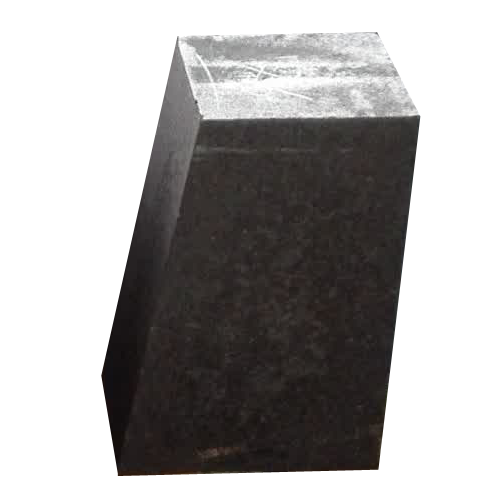

Magnesia brick

Nanme:Magnesia brick

Other name:Magnesite brick

Characters:high refractoriness,high thermal conductivity

Application:open hearth furnace,bottom and wall of the EAF,conventer, high temperature tunnel kiln,cement kiln,lime kiln, glass furnace regenerator

Magnesia zircon brick

Nanme:Magnesia zircon brick

Other name:Magnesia zircon brick

Characters:excellent corrosion resistance for alkali metal , oxides and sulfides

Application:It is used in the middle and upper part of the lattice of the glass kiln regenerator, without clogging and collapse, and the service life can reach more than 8 years. Its high temperature strength and thermal stability are better than re-combined magnesia bricks, and it has a good use prospect in the glass kiln regenerator.

Magnesia chrome brick

Nanme:Magnesia chrome brick

Other name:Magnesite chrome brick

Characters:large pores and isolated, dense, high strength, corrosion resistant and sensitive to temperature changes

Application:vulnerable parts of steelmaking electric furnace, RH, DH vacuum degassing device, secondary refining slag line parts such as VOD, LF, ASEA-SKF, AOD, steelmaking converter, cement rotary kiln and glass melting Kiln regenerators

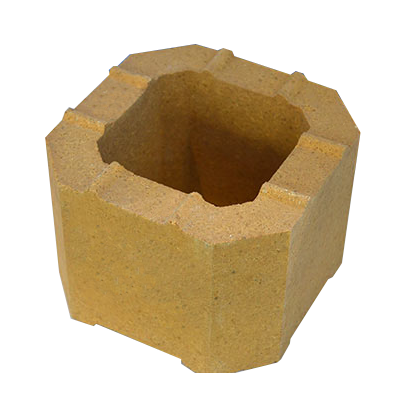

magnesia alumina spinel brick

Nanme:magnesia alumina spinel brick

Other name:magnesia alumina spinel brick

Characters:good thermal shock resistance, high refractoriness under load

Application:top of steel making open-hearth furnace and EAF, cement kiln, large-scale cement rotary kiln and non-ferrous metal smelting furnaces, etc.