Phone/WhatsApp 008618939512185

Phone/WhatsApp 008618939512185

Email: info@hcrefractory.com

Email: info@hcrefractory.com

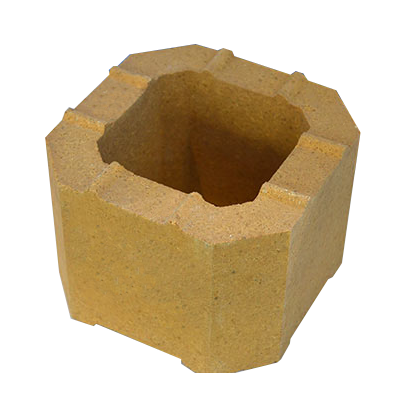

Magnesia zircon brick

Model Number:MZ-8,MZ-10,MZ-12,MZ-13

Certification:ISO 9001-14001

Minimum Order Quantity:5MT

Magnesia zircon brick description

Magnesium-zircon bricks are made of high-purity fused magnesia and synthetic magnesium-zircon sand. After high-pressure molding and high-temperature sintering, the main mineral phases are periclase, forsterite and oblique zircon, and alkali metal , oxides and sulfides have excellent corrosion resistance. It is used in the middle and upper part of the lattice of the glass kiln regenerator, without clogging and collapse, and the service life can reach more than 8 years. Its high temperature strength and thermal stability are better than re-combined magnesia bricks, and it has a good use prospect in the glass kiln regenerator.

Magnesia zircon brick | HCR MZ-8 | HCR MZ-10 | HCR MZ-12 | HCR MZ-13 | |

Chemical composition% | MgO≥ | 80 | 75 | 75 | 70 |

ZrO2≥ | 8 | 10 | 12 | 13 | |

Apparent porosity% | 19 | 18 | 18 | 18 | |

Bulk Density g/cm3 ≥ | 2.95 | 3.00 | 3.05 | 3.05 | |

Cold Crushing Strength MPa≥ | 50 | 45 | 45 | 40 | |

Refractoriness under Load ℃(0.2MPa T2) ≥ | 1600 | 1550 | 1550 | 1600 | |

Permanent Linear Change On Reheating(%)1500℃X2h | 0~+0.4 | 0~+0.4 | 40~+0.4 | 40~+0.4 | |

Thermal Shock Resistance at 100℃ water cooling | 10 | 10 | 10 | 10 | |