Phone/WhatsApp 008618939512185

Phone/WhatsApp 008618939512185

Email: info@hcrefractory.com

Email: info@hcrefractory.com

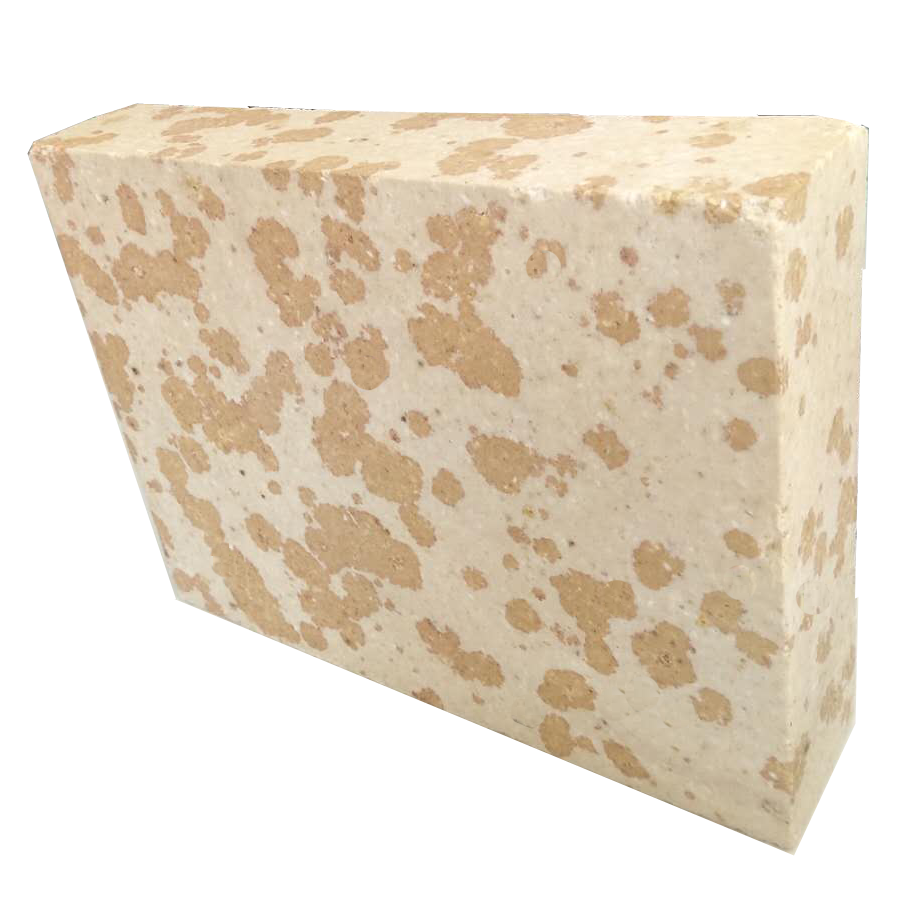

Silica brick

Model Number:S94,S95,S96A,S96B

Certification:ISO 9001-14001

Minimum Order Quantity:5MT

Silica brick description

Silica brick is a refractory product containing SiO2 as a main component. Its SiO2 content is generally not less than 93%. Silica brick is an acidic refractory material. It has strong resistance to acid slag and good resistance to oxides such as CaO, FeO and Fe2O3. However, it has poor resistance to alkaline slag erosion and is easily oxidized by Al2O3, K2O and Na2O. Destruction by the action of matter. The softening temperature of the silicon brick load is as high as 1640~1680°C, and the long-term use volume is stable under high temperature. However, silica bricks have poor thermal shock resistance and high refractoriness.

When using silica bricks, pay attention to two points: when the silica brick is at 200~300°C and 573°C, the volume suddenly expands due to the crystal transformation. Therefore, the temperature rise below 600 °C in the oven should not be too fast, when it is cooled to below 600 °C. Dramatic temperature changes should be avoided; as far as possible not in contact with the alkaline slag.

Silica brick | HCR S94 | HCR S95 | HCR S96A | HCR S96B | |

Chemical composition | SiO2 | ≥94 | ≥95 | ≥96 | ≥96 |

Fe2O3 | ≤1.5 | ≤1.5 | ≤0.8 | ≤0.7 | |

Al2O3+2(K2O+Na2O) | - | ≤1.0 | ≤0.5 | ≤0.7 | |

Refractoriness ℃ | 1710 | 1710 | 1710 | 1710 | |

Apparent porosity % | ≤22 | ≤21 | ≤21 | ≤21 | |

Bulk density g/cm3 | ≥1.8 | ≥1.8 | ≥1.87 | ≥1.8 | |

True density g/cm3 | ≤2.38 | ≤2.38 | ≤2.34 | ≤2.34 | |

CCS Mpa | ≥24.5 | ≥29.4 | ≥35 | ≥35 | |

Refractoriness under load of 0.2Mpa ℃ | ≥1630 | ≥1650 | ≥1680 | ≥1680 | |

Linear change on reburning 1500℃×2h % | 0~+0.3 | 0~+0.3 | 0~+0.3 | 0~+0.3 | |

Coefficient of thermal expansion 20~1000 ℃ | 1.25 | 1.25 | 1.25 | 1.25 | |

Thermal conductivity (1000℃,W/M.K) | 1.74 | 1.74 | 1.44 | 1.44 | |

Semi-silica brick description

Semi-silica brick refers to an aluminum-silicon refractory product having a SiO2 content of more than 65% and an Al2O3 content of 15% to 30%. Semi-silica bricks generally use tailings and pyrophyllite obtained from clay containing quartz impurities or raw kaolin, refractory clay or kaolin. Most countries in the world use pyrophyllite to make semi-silicon bricks.

The production process of semi-silicon bricks can be divided into two types: firing and not firing. Non-burned bricks are often made of water glass as a binder. The production process of fired bricks is generally the same as that of clay products, but it also has its own characteristics.

The semi-silica brick is stable in volume and has good slag resistance to acidic slag. Therefore, semi-silica bricks are widely used in coke ovens, acidified iron furnaces, metallurgical furnace flue, steel drum lining, flow steel bricks and hot metal tanks.